A leading manufacturer of automated packaging machines since 1979, Combi Packaging Systems engineers and installs affordable industrial packaging equipment customized to fit a variety of industries. Case erectors, tray erectors, case sealers, case packers and ergonomic hand packing stations, specifically for your packaging system application are manufactured at their facility in Canton, Ohio, USA.

Combi is the premier source for complete end-of-line automated packaging systems.

Systems for Food Packaging

Gain Affordable Performance with Combi’s Customized Food Packaging Equipment From bakery, dairy, snack and frozen foods to meat and poultry products, Combi Packaging Systems is a leading manufacturer of end-of-line food packaging machines. We are equipped to engineer and build your most basic line to your most demanding or delicate food packaging machinery application.

Combi offers special food packaging equipment features:

- Affordable, customized design

- Automatic or semi-automatic case loaders & packers

- Product collation and accumulation, including upstacking and downstacking

- Modular packing heads for quick changeovers

- Easy handling of flexible packaging

- Stainless steel frame and NEMA 4 compliant washdown components

At Combi, we specialize in handling products that require special orientation or precise placement, including flexible bags and pouches, bottles, cartons, blister packs and gable top cartons. And, for greater flexibility our modular packing heads make it possible to pack multiple products on the same machine. For washdown environments, our frames are constructed from U.S. manufactured stainless steel and NEMA 4 compliant components. For integration into your food manufacturing line, Combi offers affordable automatic and semi-automatic food packaging equipment including case erectors, case sealers, case packers and the packing industry leading Ergopack® Hand Packing System.

Systems for Chemical Packaging

Combi Packaging Systems is a leading manufacturer of end-of-line chemicals packaging equipment for the chemical industry. Whatever the container type, including spray bottles with trigger nozzles, aerosol or steel cans, glass or plastic bottles of all shapes and sizes and more, we can engineer affordable, customized chemical packaging equipment for a basic line or your most demanding, three-shift chemicals packaging application.

Combi chemical packaging machinery features:

- Affordable, customized design

- Automatic or semi-automatic case loaders & packers

- Product collation and accumulation, including upstacking, downstacking and roll-on collation

- Modular packing heads for flexibility and quick changeovers

- Skillful handling of virtually any container shape or size

- Frame option of U.S.-manufactured stainless steel with NEMA 4 compliant washdown components

For easy integration into your chemical manufacturing line, Combi offers customized automatic and semi-automatic chemical packaging machinery, including case erectors, case sealers, case packers and the industry-leading Ergopack® Hand Packing System.

Systems for Contract Packaging

Combi Packaging Systems makes customized end-of-line packaging equipment affordable for contract packaging companies that must maintain volume while meeting tight deadlines and budgets. Tailored to your needs, our semi-automatic and automatic case-handling equipment increases production and efficiency and reduces labor costs and product damage.

Combi packaging equipment features that enhance contract packaging production include:

- Custom-designed semi-automatic or automatic packing equipment for affordable automation of a manual operation.

- Modular packing heads and equipment design for flexibility with quick changeovers and setting up new production lines.

- Optional U.S.-manufactured stainless steel frames and NEMA 4 compliant washdown components.

Combi is your single source for automatic and semi-automatic case erectors, case sealers, case packers, and case labelers for contract packagers that easily integrate with existing lines.

Case Erectors

Combi Model 2-EZ®HS

Case Size Range: min 8 x 6 x 5, max 24 x 16 x 18

Speed: up to 25 cpm *with speed up kit

Features:

- EZ Load Walk-In 50″ powered case magazine

- Positive four flap closing

- Heavy duty welded steel frame construction (lifetime warranty)

- Servo driven carriage assembly

- Dual belt drive case indexing

- AB Panelview OIT provides production and diagnostic feedback

- Self-cleaning vacuum system

Model 2-EZ®SB

Case Size Range: min 8 x 6 x 5, max 24 x 16 x 18

Speed: up to 15 cpm

Features:

- EZ Load Walk-In 50″powered case magazine

- Positive four flap closing

- Heavy duty welded steel frame construction (lifetime warranty)

- Pneumatic carriage assembly

- Dual belt drive case indexing

- AB Panelview OIT provides production and diagnostic feedback

- Self-cleaning vacuum system

Model 2-EZ®SB and 2-EZ®HS Right hand/Left hand Option

- Speed 17-20 cases per minute

- Opposite hand case modification includes RH/LH case forming that self-adjusts through menu setting on OIT

- No overhead cross members in doorways provides easy access for maintenance

- Hinged case hold down plate allows for easy tape head removal

- Self-cleaning vacuum system with vacuum generator consumes conservative amount of air

- 240 Volt / 3 ph / 20A

Model 2-EZ®XL

Case Size Range: min 13 x 10 x 6, max 24 x 20 x 18

Speed: up to 15 cases per minute* with servo

- Large case capabilities

- 50″ EZ Load Walk-In Powered Case Magazine with Motorized Magazine Elevation

- Dual belt drive (XL) or servo driven (XL-HS) carriage assembly

- Heavy duty welded steel frame construction (lifetime warranty)

- Self-cleaning vacuum system with air purge

Semi-Automatic Case Packers

Ergopack® Hand Pack Stations

Case Size Range: min 8 x 6 x 5, max 24 x 20 x 18

Speeds: up to 20 cases per minute* operator dependent

- Seamless integrates case erector, hand pack station and case sealer into a compact, ergonomic work cell

- Operators never touch a case, hands free indexing system presents case and product in front of operators

- Ergonomic design: minimizes reach and wrist movement, reducing threat of repetitive motion injuries and medical costs associated with treatment

- Hand packing assures 100% product inspection

RTE Sanitary Ergopack®

This machine, first in the industry, helps food and pharmaceutical producers meet the highest levels of hygiene and safety. Features include:

Cleanable Constructed to ensure equipment can be washed and sanitized over the lifetime of the equipment

Open Design Construction SSTL materials are corrosion resistant and compatible with cleaning and sanitizing chemicals

Accessible Parts are accessible to disassemble for inspection and cleaning without the use of tools

Water Shedding Surfaces Covers are self-draining to assure product, water and liquids do not accumulate or pool on equipment surfaces

No Hollow Areas – No hollow areas or penetrating rivots or fasteners used

No Niches – Equipment is free of niches and all welds are continuous and fully penetrating

Hygienic Maintenance Enclosures Control panels are sloped or pitched and easily cleaned and sanitized

EZ-Pack Case Former

This is a semi-automatic solution for manual packing lines. The EZ-Pack allows one person to form, pack and seal corrugated cases in a single operation. A cost-saving step up from manually erecting and taping boxes, this value priced pack station boosts efficiencies while reducing the threat of repetitive stress injuries. Ideal for distribution centers. Available in stainless steel construction.

Case Size Range: min 8 x 6 x 5, max 30 x 24 x 18

Fully Automatic Case Packers

Servo Pick and Place Packers

Combi offers compact, top loading case packers ideal for packing product in multiple layers into corrugated cases while accommodating a wide range of case sizes and pack patterns.

- Linear servo system capable of 25 picks per minute

- Vacuum generator used for case pick

- Quick release change parts for fast product changeovers

- Two axis servo module with high torque brushless motor

- Allen Bradley PanelView Plus 6 color operator interface

- 50″ EZ Load, walk-in powered case magazine

- Available with integrated case erector and multiple packing heads

Drop Packers

Combi’s drop packers pack a large variety of rigid round and non-round containers in various sizes, shapes, weights and materials easily and quickly in large cases or trays at speeds up to 30 cpm.

- Pack multiple products on one machine with modular packing heads

- Digital readouts on case erector assist with quick changeovers

- Available with or without integrated case erector; high speed servo carriage assembly

- Optional Soft drop lowerator for heavy products (mechanical gripper or vacuum cups)

- Optional product diverter counts and indexes product from one lane up to 8 individual lanes

- Heavy-duty case lift assembly with powered case discharge

- Dual belt drive bottom case sealing

Horizontal Loading

Combi’s side loaders pack cylindrical or round objects, maintaining horizontal orientation, as well as smaller cartons and blister packs that can be difficult to collate. Custom collation solutions are tailored to the specific product and Combi’s patented case placement system accommodates a diverse range of case types and sizes.

- Custom product collation and orientation

- Company modular design with optional integrated case erector

- Quick changeovers including optional automatic changeover

- Full guarding with safety interlocks

- EZ Load powered case magazine

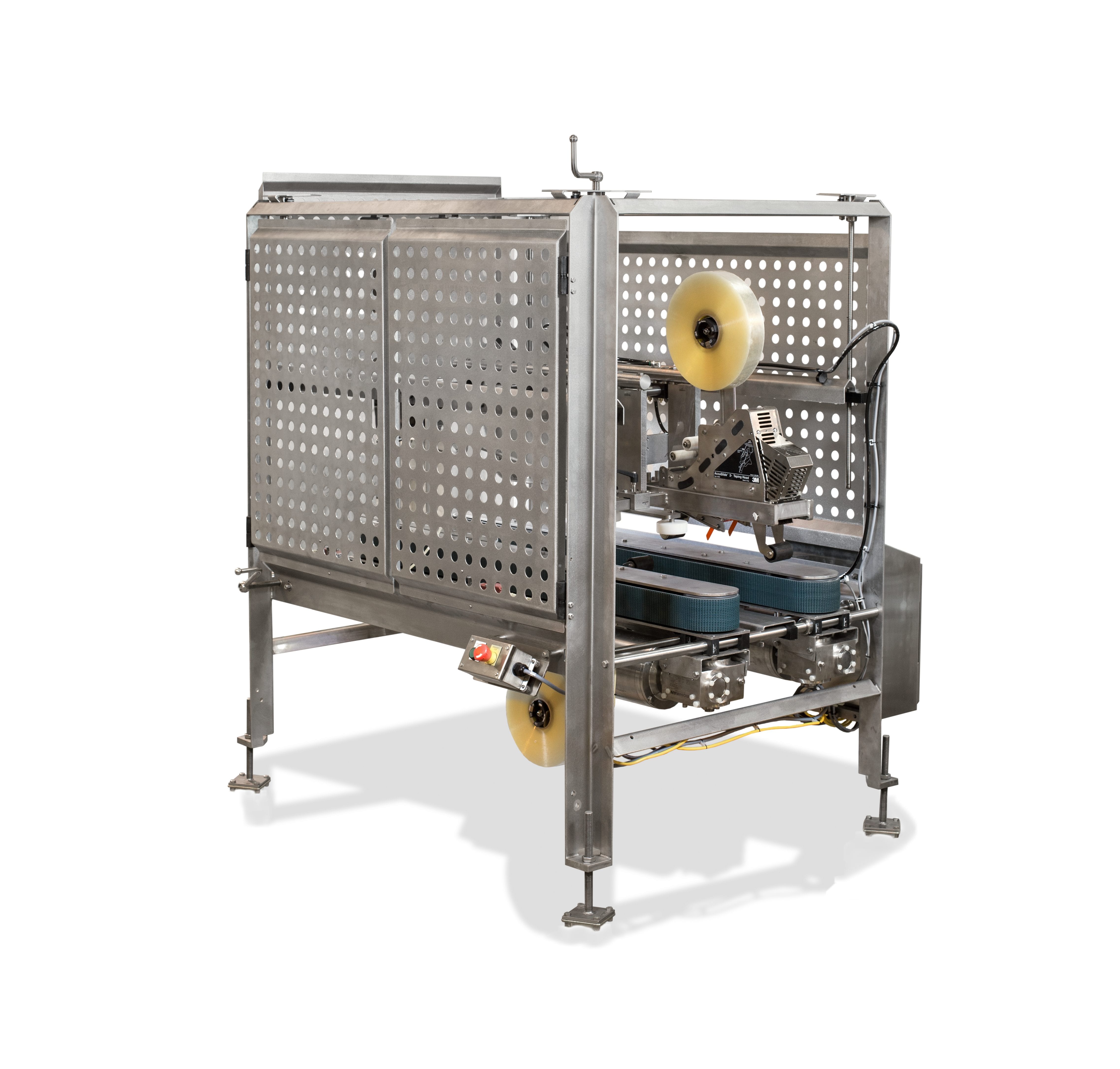

Fully Automatic Case Sealers

TBS-100FC Case Sealer

Whether you need a stand-alone case sealer to boost productivity or a sealing solution integrated at the end of your Combi case packing line, Combi TBS case sealers offer a reliable solution for your needs.

- Heavy-duty tubular steel construction

- Quick changeovers tape head and side belts adjust simultaneously resulting in one less manual adjustment

- Oversized drive motors with adjustable belts

- Safety interlocked guarding

- 3M Accuglide II tape heads

- Automatic top and/or bottom sealing

- Optional Nordson ProBlue Melter Glue System

Robotics

Ergopack Robotic Pick and Place Packing Station

Increased global competition is driving leaner operating efficiency in today’s manufacturing plants. To gain efficiences, robots are being used more frequently in more and more plants for case packing and palletizing because of the increased throughput, vision and cost savings today’s robotic technology offers. These same plants are finding that human workers can work right alongside robots, with proper guarding, as they each perform a task for which they are best suited.

In partnership with robotic automation provider Motion Controls Robotics, Combi Packaging Systems offers a Robotic Pick and Place Packing feature to fully automate case packing operations that may require verifying lot or serialization numbers, varying pack counts, creating retail ready packages, or automating tasks that are difficult or unsafe for humans.

For greater flexibility and greater throughput, companies’ existing Ergopack Hand Packing Stations can be retrofitted with this robotic packing unit. The Fanuc robot can be used during times when hand packing is unavailable or impractical.

RCE Robotic Random Case Erector

The RCE Robotic Random Case Erector combines a FANUC M20iA/20 six-axis robot with multiple case magazines and a bottom flap folder with integrated 3M tape head. The FANUC robot has a flexible end of arm tool to pick and erect multiple cases, eliminating the need for multiple erectors, the floor space they consume and costly changeover downtime. The standard system features one to six Combi powered case magazines, accommodating six different case sizes, project dependent. The RCE Random Case Erector System includes:

Standard Features

- FANUC M20iA/20 six-axis Robot

- Flexible End of Arm Tooling with Vacuum and Dropped Case Detection

- Dual Gravity Case Magazines

- Bottom Flap Folder with 3M Tapehead

- Allen-Bradley PanelView Plus 1000 touchscreen

- Fixed robot Base, anchored to floor

- Programming for Robot, PLC/PMC, HMI and Vision

- Robot Perimeter Barrier Guarding with Safety Interlocking Doors

- On-Site Training and Support