Midwest Packaging Solutions is proud to carry the full line of Squid Ink’s Industrial Inkjet Printers! Squid Ink specializes in the manufacture of industrial inkjet printers and high quality industrial inkjet inks for the packaging industry. Their products are designed to provide reliable cost-effective solutions to your industrial applications. Squid Ink has relied on a wealth of knowledge and experience in the inkjet industry to design a full family of Large Character and Hi-Resolution printing systems. Additionally, Squid Ink has been able to formulate the most comprehensive line of Hi-Resolution, Piezo, and Large Character fluids in the product identification market today.

Hi-Resolution Printers

The CoPilot Hi-Resolution Printing System

Squid Ink’s CoPilot uses proven Xaar piezo technology to print up to .7” of hi-resolution characters, razor-sharp text, scannable bar codes, and great looking logos at 185 dpi and a 4.3″ full color touchscreen provides access to the system’s internal messages and print functions. Messages are created and edited on Squid Ink’s easy-to-use Orion™ PC Software and transferred via Ethernet or USB device. For larger applications, multiple CoPilot printing systems can be connected via Ethernet or wirelessly and controlled through one central Orion print station.

The Competitive advantage

Squid Ink introduces the CoPilot ™ printing system, a feature-rich hi-resolution printing system available at an entry level price. Squid Ink’s CoPilot printing system offers several advantages over competitive HP or Lexmark – based printing systems. With the CoPilot, users can expect 30% larger print, increased throw distance, 5 times larger ink volume, the ability to upgrade to a 2nd printhead, and much more

Printing Made Easy

CoPilot’s 4.3” full color touchscreen provides access to the system’s internal messages and print functions. Messages are created and edited on Squid Ink’s easy-to-use Orion™ PC Software and transferred via Ethernet or USB device. For larger applications, multiple CoPilot printing systems can be network connected via Ethernet or wirelessly and controlled through one central Orion print station.

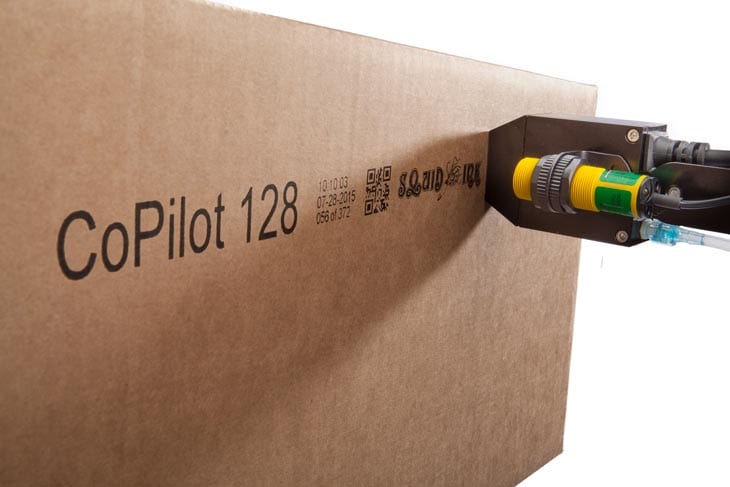

The CoPilot 128 Hi-Resolution Printing System

The CoPilot 128 ink jet printing system offers the durability, versatility and productivity that you have come to rely on from Squid Ink. Whether you are printing lot codes on coated cartons, bar codes on corrugate cases, or product information and logos on PVC pipe you’re sure to find the right solution with Squid Ink’s new CoPilot 128.

Industrial Design, User Flexibility

The system is capable of running oil-based or solvent-based inks to print up to 185 dpi at 135ft /min on a variety of substrates. For non-porous applications, users have the option of utilizing Squid Ink’s solvent-based inks to print a number of pigmented inks on a variety of non-porous products like, coated cartons, plastics, glass, shrink wrap, metals, and more. Squid Ink’s PZ-1000 ink for porous substrates offers low-maintenance performance, eliminating the need for auto-priming functions and offering better ink utilization than competitive systems.

Maximize Your Uptime

The CoPilot 128 is designed to meet the harsh demands of your application. The printer features a durable touchscreen, industrial strength printhead construction, and print engines designed for industrial applications, not office applications. You can be confident that CoPilot 128’s rugged design will withstand the most abusive industrial environments while providing superior quality print. The CoPilot also features a large 500ml cartridge or bag ink system. The generous ink volume allows users to keep their line running, reducing downtime and maximizing ROI.

The CoPilot 256 Hi-Resolution Printing System

The CoPilot 256 ink jet printer is designed to print superior quality hi-resolution characters on either porous or non-porous surfaces. With up to 2.8” of total print height and the ability to print on both sides of the substrate in a single pass, the CoPilot 256 is designed to work as an integral part of your day-to-day packaging operation.

Increased Application Versatility

The system is capable of running oil-based or solvent-based inks to print up to 2.8” (1.4” from a single head) of hi-resolution characters, razor-sharp text, scannable bar codes, and great looking logos at 185 dpi. For non-porous applications, users have the option of using Squid Ink’s solvent-based inks for printing on a variety of products like coated cartons, plastics, glass, shrink wrap, metals and more. Squid Ink’s PZ-1000 ink for porous substrates offers low-maintenance performance, eliminating the need for auto-priming functions and offering better ink utilization than competitive systems.

User-Friendly System

CoPilot 256’s 4.3” full color touchscreen provides access to the system’s internal messages and print functions. Messages are created and edited on Squid Ink’s easy-to-use Orion™ PC Software and transferred via Ethernet or USB device. For larger applications, a virtually unlimited number of CoPilot 256 printing systems can be connected via Ethernet and controlled through one central Orion™ print station.

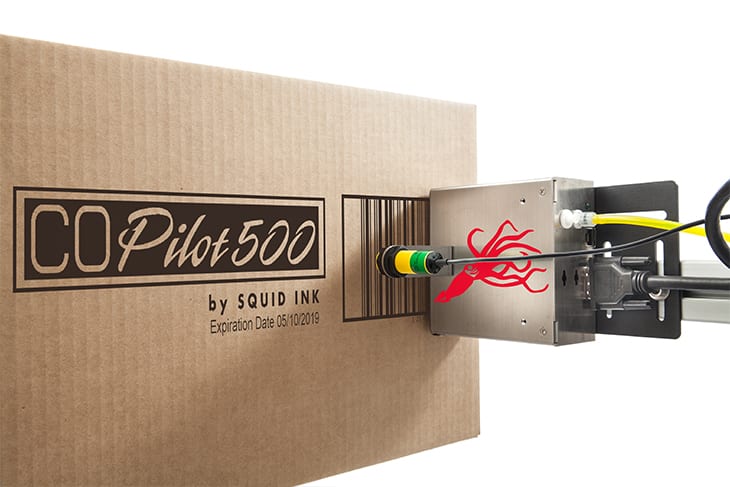

The CoPilot 500 Hi-Resolution Printing System

Squid Ink’s CoPilot 500 printing system is designed to print superior quality hi-resolution with up to 2.8” of print height per printhead and the ability to run up to 2 printheads from one controller. The CoPilot 500 offers a versatile, yet cost effective solution for your coding and marking applications.

Application Versatility

The system is capable of running oil-based or solvent-based inks to print up to 5.6” (2.8” from a single head) of hi-resolution characters, razor-sharp text, scannable bar codes, and great looking logos at 180 dpi. For non-porous applications, users have the option of utilizing Squid Ink’s solvent-based ink to print on a variety of non-porous products like coated cartons, polystyrene, and more. Squid Ink’s PZ-1000 ink for porous substrates offers ultra-low maintenance, eliminating the need for auto-priming functions and offering better ink utilization than competitive systems.

Engineered For Maximum Uptime

The CoPilot 500 is designed to meet the harsh demands of your application. The printer features a durable touchscreen, industrial strength printhead construction, and simple ink delivery system for industrial applications. You can be confident that CoPilot 500’s rugged design will withstand the most abusive industrial environments while providing superior quality print. The CoPilot 500 also features a large 500ml cartridge. The generous ink volume allows users to keep their line running, reducing downtime and maximizing ROI.

The AutoPilot Hi-Resolution Printing System

Squid Ink’s AutoPilot printing system will print up to .7″ of hi-resolution characters, razor-sharp text, scannable bar codes, and great looking logos. Users can run up to two printheads from a single touchscreen controller to maximize efficiency and print on opposite sides of a case if needed. The AutoPilot is capable of running oil-based or solvent-based inks to print on a variety of substrates. Best of all, AutoPilot’s 180 dpi print resolution meets your application needs for quality coding and marking.

The AutoPilot Advantage

Squid Ink introduces the AutoPilot™ printing system, a feature-rich hi-resolution printing system available at an entry level price. Squid Ink’s AutoPilot printing system offers several advantages over competitive HP® or Lexmark® – based printing systems. With the AutoPilot, users can expect 30% larger print, the ability to upgrade to a 2nd printhead, message programming via touchscreen user panel, the ability to print bar codes with standard systems, the ability to print on a variety of porous and non-porous surfaces, and much more.

Maximize Your Uptime

The AutoPilot is designed to meet the harsh demands of your application. CE, TUV, and FCC certified, the AutoPilot features a durable touchscreen, industrial strength resin printer construction, and allows the AutoPilot to operate in the most extreme factory environments. In addition, Squid Ink’s PZ-1000 ink for porous substrates offers low maintenance performance, eliminating the need for auto-priming functions and offering better ink utilization than competitive systems. You can be confident that AutoPilot’s rugged design will withstand the most abusive industrial environments while providing superior quality print.

905 Series for Kwik Lok Systems Bakery

An Ideal Solution for Bakeries

The 905 Series CoPilot UV LED Curing System integrated with Kwik Lok’s 872 or 893 Automatic Bag Closing Machine provides an ideal solution for bakeries printing sell by dates, suggested list prices, and 2D bar codes on bakery bag closures.

Make a Mark That Lasts

Squid Ink’s UV LED curing technology features a low maintenance ink cured only by UV LED light. The ink won’t dry until it comes in contact with the UV light, meaning a lower maintenance solution than all other ink jet technologies. This instant LED curing ink leaves a permanent mark that is impervious to environmental factors such as sunlight, water, moisture, temperature, and contains virtually no VOCs, making it ideal for food applications. Additionally, the 905 Series CoPilot system utilizes easy-to-use software modified specifically for the baking industry for easy message programming and recall.

Out With the Old, In With the New

UV LED technology offers several advantages over existing TTO (thermal transfer overprint) systems currently used in bakery applications. Squid Ink’s 905 Series CoPilot system does not require compressed air, making it an easy install anywhere in the plant. In addition, the 905 Series offers 20-25 times fewer ink/ribbon changes, and up to 5 times lower cost per print. Typical cost per print is 20 cents per 1,000 loks. Add in a longer printhead life span and no work stoppages for ribbon breaks, and users will enjoy increased savings on their initial and ongoing operating costs.

Designed for Durability

Squid Ink’s 905 Series CoPilot UV LED Curing System is designed to meet the demands of your application. You can be confident that the 905 Series CoPilot’s rugged design will withstand your baking environment while providing superior quality print and UV curing. For ease of integration, the 905 mounts directly to Kwik Lok’s 872 or 893 Closure Machines and requires no need for preheating or compressed air. The 905 UV LED system can be programmed to run in manual, semi-automatic, or automatic mode to match the operation of your manufacturing line. For quick start-ups, 905’s fast response functionality means that the system can be powered on and ready to go at an instant, eliminating downtime and increasing your ROI.

905 Series for Kwik Lok Systems Produce

An Ideal Solution for Produce Packing

The 905 Series CoPilot UV LED Curing System integrated with Kwik Lok’s 865 Automatic Bag Closing Machine provides an ideal solution for produce packers printing sell by dates, suggested list prices, 2D bar codes, and more on fresh produce bag closures.

Make a Mark That Lasts

Squid Ink’s UV LED curing technology features a low maintenance ink cured only by UV LED light. The ink won’t dry until it comes in contact with the UV light, meaning a lower maintenance solution than all other ink jet technologies. This instant LED curing ink leaves a permanent mark that is impervious to environmental factors such as sunlight, water, moisture, temperature, and contains virtually no VOCs, making it ideal for food applications. Additionally, the 905 Series CoPilot system utilizes easy-to-use software modified specifically for the baking industry for easy message programming and recall.

Out With the Old, In With the New

UV LED technology offers several advantages over existing TTO (thermal transfer overprint) systems currently used in bakery applications. Squid Ink’s 905 Series CoPilot system does not require compressed air, making it an easy install anywhere in the plant. In addition, the 905 Series offers 20-25 times fewer ink/ribbon changes, and up to 5 times lower cost per print. Typical cost per print is 20 cents per 1,000 loks. Add in a longer printhead life span and no work stoppages for ribbon breaks, and users will enjoy increased savings on their initial and ongoing operating costs.

Designed for Durability

Squid Ink’s 905 Series CoPilot UV LED Curing System is designed to meet the demands of your application. You can be confident that the 905 Series CoPilot’s rugged design will withstand your baking environment while providing superior quality print and UV curing. For ease of integration, the 905 mounts directly to Kwik Lok’s 872 or 893 Closure Machines and requires no need for preheating or compressed air. The 905 UV LED system can be prgrammed to run in manual, semi-automatic, or automatic mode to match the operation of your manufacturing line. For quick start-ups, 905’s fast response functionality means that the system can be powered on and ready to go at an instant, eliminating downtime and increasing your ROI.

DOD Large Character Printers

The SQ/2 Drop on Demand Large Character Printing System

The SQ/2 large character ink jet system prints high quality dot-matrix characters on a variety of products at a cost-effective price. The SQ/2 offers the lowest price per printed character in the industry today. Users can choose between two models: a water-based model for printing on porous surfaces like corrugated cartons, or as a solvent-based system for printing on non-porous product like plastics, stretch wraps, metals and more.

User Flexibility

SQ/2 users also have the option of choosing from several printhead configurations. Three different print sizes are available: 3/4”, 1/2”, or 3/8” character height. All printheads are capable of printing both a 7 x 5 and 5 x 5 character matrix, offering print sizes ranging from 1/4”″to 3/4” in height. Users also have the flexibility to run one or two printheads at any time. All of these components are field-installable for future upgrade to meet your application’s changing requirements.

No More Service Calls

The SQ/2 was engineered inside and out for industrial strength operation. Heavy-duty gauge coated steel cabinetry ensures continuous operation in harsh, real world environments. If the printer does fail, a fix can be completed in less than five minutes. Quick and easy-to-install replacement printheads, PC cards and air pump modules minimize downtime and eliminate costly service calls. Best of all, the water-based SQ/2 utilizes Squid Ink’s patented SQ-60™ no-clog ink, allowing users to leave the ink in their printheads for an extended period of time without flushing or cleaning, making it the most cost-effective, low maintenance ink jet printing system available today.

Vector XII Drop on Demand Large Character Printing System

The Vector XII large character industrial ink jet printer offers the modularity and versatility that manufactures and contract packagers need. With the ability to print up to 12 lines from 6 print heads, the Vector XII large character ink jet printer has the tools you need to get the job done. 1″ and 1 3/4″ print head sizes are available offering six print sizes ranging from 1/2″ to 1 3/4″. The Vector XII system can also be programmed and maintained with a PC through a standard RS-232 port.

User Flexibility

Vector XII users have the option of choosing from several different printhead combinations. Two different printhead sizes are available: 1”or 1 3/4”″ character height. Each printhead is capable of printing at 100%, 40%, or 26% character height, offering six print sizes ranging from 1/2”″ to 1 3/4”″. Users also have the flexibility to run up to 6 different printheads of any size at the same time. No other system has this versatility. All of these components are field installable for future upgrade to meet your application’s changing requirements. And unlike any other DOD printing system in the industry, Vector XII offers up to 12 lines of print from a single controller.

User-Friendly System

The Vector XII is designed for simple day-to-day operation. Vector XII’s state-of-the-art input device provides quick and easy message programming and retrieval for up to 128 messages. Resident software accessed from the hand-held input device walks users through a series of prompts to program and save each message for printing on-demand. The system can also be programmed and maintained with a PC through a standard RS-232 port. Vector XII’s easy-to-use design and user-friendly software makes everyone involved a smooth operator.

The SQ/2 Scorpion Drop on Demand Large Character Printing System

The SQ/2 Scorpion industrial large character ink jet printer includes upgraded software delivering more features. SQ/2 Scorpion users have the option of choosing from several print head configurations. Five different print head sizes are available, offering 12 print sizes ranging in height from 3/8″ up to 1 3/4″. The 1600 Series print heads offer split-line capability and the option of printing full-size characters or half-size characters with the same print head.

True Versatility for Your Needs

SQ/2 Scorpion users have the option of choosing from several printhead configurations. Five different print sizes are available: 3/8”, 1/2”, 3/4”, 1” or 1-3/4” character height. All printheads are capable of printing at 100% or 70% character height, offering 12 print sizes ranging from 1/4” to 1-3/4” in height. The 1” and 1-3/4” (1600 Series) printheads even offer split-line capability and the option of printing full-size characters or half-size characters with the same printhead.

More Brain. More Brawn.

The SQ/2 Scorpion is upgraded with software features that ink jet users need most: increased memory locations for up to 128 messages, the ability to automatically print a manufacturing date and an expiration date, as well as a shift organizer to automatically separate and code different work shifts within your packaging operation. The SQ/2 Scorpion also comes standard with a shaft encoder input for packagers using a variable speed conveyer. On the hardware side, the SQ/2 Scorpion features a built-in central air gauge to view regulated air pressure within the system and fine-tune your print quality.

CIJ Small Character Coders

The Streamline 5 CIJ Small Character Printing System

Squid Ink’s Streamline 5 CIJ printing system is designed to print superior quality small characters on a variety of substrates: porous, non-porous, smooth, textured, curved, concave and more. Printing up to 5 lines of text, the Streamline offers a reliable, yet cost effective solution for virtually any small character, primary package coding application.

A New Level of Technology

Streamline 5 offers users the latest in today’s technology. Unlike any other CIJ printer on the market, Streamline 5 does not require a built in display screen. Streamline 5 operates with a wireless or wired touchscreen tablet running Squid Ink’s powerful Orion software, allowing users the option of controlling their printers on the production floor, or networking multiple systems from one central location. One tablet may be used to communicate with multiple Streamline printers or any other Squid Ink case coding printer using the Orion software platform.

Maximize Your Uptime

The Streamline 5 is designed with the low maintenance features that users have come to rely on from Squid Ink. Streamline’s self-cleaning printhead with CleanJet™ maintenance routine allows quick and easy automatic start-up and shutdown. A simple press of a button commands the printer to go through a start-up cycle or flush the system for shutdown. When routine maintenance is required, components can be swapped out within minutes eliminating the need to purchase expensive filter and pump assemblies or schedule costly service calls. In addition, annual PMs can be made in minutes simply by swapping the entire ink system with an affordably priced refurbished system.

Laser Coders

The SQ-10 & SQ-30 Laser Coding Systems

Squid Ink’s SQ-10 laser coding system is designed for high speed food and beverage, pharmaceutical, cosmetic, and other primary coding applications. Squid Ink CO2 lasers can permanently mark onto paper, cardboard, plastic, and more.

Application Versatility

- Permanent coding of text, time and date, bar codes,

serial numbering and more - Quick and easy installation for both stationary and moving products

- Easily fits into production environments where space is limited

- Laser head can be rotated 90° in less than 5 minutes

Reliable & Economical

- No ink/consumables for lower cost of ownership

- Clean and eco-friendly coding system

- Rugged cast aluminum controller body

- IP54 rating ensures maximum reliability and uptime in demanding applications

- Integrated key switch and interlock relay for increased safety on the production floor

The SQ-LFX Laser Fume Extraction System

Squid Ink’s SQ-LFX Laser Fume Extraction System pairs with Squid Ink’s laser marking systems and is designed to exceed the fume extraction demands of your laser marking application. Manufactured by industry leader Purex™ for Squid Ink, the SQ-LFX fume extractor is one of the most technically advanced compact laser fume extractors on the market.

Ease of Operation with IQ

The SQ-LFX has been enhanced with the highest grade HEPA and carbon filter technology and packs a powerful range of unique features into one compact unit. The informative graphic display gives operators a clear view of the operation to provide a quick-read visual display of how the system is functioning. For further insight into your operation, the system provides a cache of analytical data, enabling users to view performance and operating parameters for evaluation purposes.

Performance With Safety In Mind

The SQ-LFX design features keep your air filtration system running at peak performance levels while reducing your maintenance downtime. Automatic Flow Control technology maintains a constant extraction rate that ensures the safe capture and removal of hazardous fumes by balancing the system’s airflow rates with the type, depth, and surface area of SQ-LFX’s carbon filters. To increase your filter life, the unit is designed with Adjustable Air Flow that allows the system to be easily adjusted for various applications. SQ-LFX was also designed with Reverse Air Flow to prevent condensation while prolonging filter life.

Thermal Transfer Overprinters

Squid Ink Thermal Transfer Overprinter

The Squid Ink line of TTO printers offer consistent, high resolution print quality for users in a number of industries including food, healthcare, cosmetic, pharmaceutical and more. When you need to print lot codes, date codes, barcodes, or logos on flexible film, you’re sure to find the right solution with Squid Ink’s new TTO series of printers.

Versatile Print Options

Squid Ink offers intermittent and continuous TTO equipment capable of printing 32mm x 46mm with our SQ-32i model, and 32mm x 106mm with our SQ-32c continuous model. For applications requiring more print information, the SQ-53i TTO printer offers a print area of 53mm x 53mm and 53mm x 106mm with the SQ-53c continuous model. The intermittent SQ-32 and SQ-53 models are capable of printing at speeds of up to 500PPM.

Make Your Mark

Squid Ink TTO coders use thermal printheads paired with thermal transfer ribbon to apply a consistent and reliable mark on your products. The SQ-32 and SQ-53 models offer high speed printing of incredible looking variable text, serial numbers, barcodes, and graphics at a razor-sharp 300 DPI. Our TTO machines also feature arm ribbon control to prevent ribbon breakage, and a 600 meter length ribbon provides long run times between ribbon changes. Best of all, Squid Ink’s TTO printers minimize the ribbon gap between prints to 0.5mm or less to save ribbon and increase efficiency.

UV LED Curing Systems

The Squid UV LED Curing System

The Squid UV LED Curing System from Squid Ink offers accurate and consistent UV curing across a variety of commercial and industrial applications. Whether you need to cure ink on metal, glass, automotive products, plastics, electronics and more, you’re sure to find the right solution with Squid Ink’s new UV Curing System.

High Curing Quality

Squid UV is capable of curing inks in a 20mm x 80mm area from a single illumination module that can be doubled to cure an area of 40mm x 80mm or 20mm x 160mm with the addition of a second system. The system features an advanced LED module to provide consistent luminance, resulting in a reliably cured product, every time. The stability of UV LED technology makes the output of electricity predictable and stable, avoiding problems associated with conventional halogen heat lamp drying.

Low Running Cost

UV LED technology provides a stable and efficient way of curing CIJ, Piezo, and Thermal inkjet inks. The integrated super cooling system considerably lowers the unit’s operating temperature to extend the life of the machinery while reducing maintenance costs. The use of UV LED curing results in a significant savings in power reduction, and time and money spent replacing lamps becomes obsolete due to the 20,000+ hour illumination runtime. For comparison, Squid UV curing systems use about 75% less energy than typical UV arc lamp curing.

Ink Delivery Systems

The Titan Ink Delivery System

The TITAN provides users with an alternative ink source for the Marsh Unicorn™, Little David Microjet™ and other entry-level DOD ink jet printing systems.

Squid Ink Lets You Have It Your Way

Customers asked for it and Squid Ink delivered. Squid Ink’s Titan Ink delivery system provides users with an alternative ink source for the most common entry-level dot matrix ink jet printing systems. Using ink packaged in proprietary OEM containers can be very expensive. Squid Ink’s Titan bypasses their proprietary ink containers, connects directly to the printer, and allows users to run large volume ink containers at a low cost.

High-Quality Ink For Less

Customers using Squid Ink DOD fluids often experience longer machine life, less downtime and lower maintenance costs than when they use competitive products. When the Squid Ink bottle runs low, users can pour any remaining ink into the next bottle being used. This offers 100% utilization of every drop of Squid Ink. When Squid Ink bottles are empty, users simply discard empty un-covered bottles in the garbage. Competitive bottles always contain some residual ink and will not dry out. These bottles are considered a hazardous waste and must be discarded accordingly.

Material Handling

Eastey Conveyor Series

Eastey’s variable speed conveyors offer the quality that you have come to rely on from Eastey. The EC Series conveyors offer a reliable stand-alone product transport for primary or secondary product marking, and make a convenient add-on infeed or exit feed conveyor to existing case taping or shrink wrapping equipment.

Designed for Inkjet Applications

The EC Series design is perfect for integration with ink jet printing equipment. Each conveyor comes

pre-drilled in multiple locations to easily add printer and encoder mounting brackets. The smooth drive belt provides consistent speed for reliable, scannable barcoding and product transfer. Systems include a lower shelf with holes for cable management and provide storage for supplies such as spare printheads, printer and UV LED control boxes, spare ink, and more.

Ease of Use

The conveyors utilize an endless belt with self-tracking V-groove for consistent alignment. The variable speed drive motor is adjustable up to 100 fpm for a variety of applications. The unit also features a magnetic control box that can be mounted on either side of the conveyor. Conveyor legs are adjustable from 20″ up to 33.5″. The system is designed to keep maintenance to a minimum and provide a fast and efficient method of product transport.

Vertical Case Transport System (VCTS)

Eastey’s Vertical Case Transport System allows users to print on two sides of a case eliminating the need for pre-printed cases or expensive labeling equipment and supplies. Adjustable width settings allow users to print on cases ranging in size from 10″x 10″ up to 33″ x 40″.

Automatic Operation

Designed for off-line case printing, the VCTS automatically feeds blank cases through a print station that is ideal for mounting hi-resolution inkjet printers and offers the ability to print virtually anywhere on either side of the case. Open access to printheads allows for easy maintenance and quick adjustments. The VCTS also features an input hopper that can hold up to 90 flat single wall cases and can easily be reloaded by one person.

Easy to Program

The VCTS includes a programmable counter that keeps track of batch quantities, rate of operation, and elapsed run time, allowing users the ability to customize case runs. The system can be easily programmed to shut down when the maximum count is reached. The VCTS batch counter is the ideal solution for users looking to print a message on specific number of cases while eliminating the need for manual case counting.